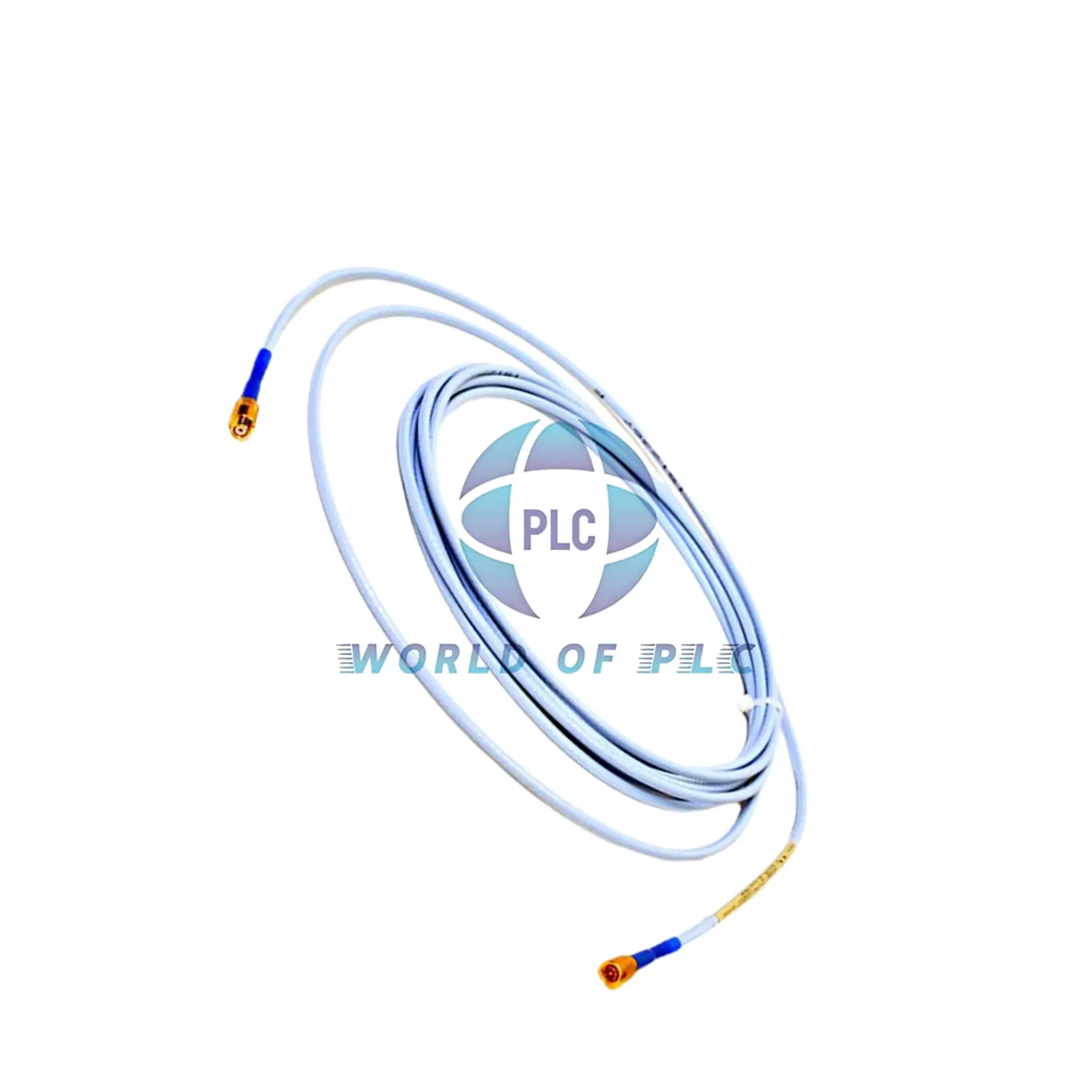

Bently Nevada 3300 XL FluidLoc Proximity Probe (P/N: 330701-00-26-10-11-05)

Advanced Sealed Sensing Technology

US-engineered 11mm probe with FluidLoc cable system prevents oil migration. Global certifications included for hazardous environments.

Part Number Hierarchy

- Base: 330701 (11mm Probe Series)

- Case: 00/26 → 0.0″ Unthreaded / 2.6″ Length

- Cable: 10 → 1.0 Meter Length

- Connection: 11 → ClickLoc + FluidLoc

- Certification: 05 → Multiple Approvals

Critical Specifications

- Thread: 1/2-20 UNF

- Resistance: 5.9Ω ±0.5Ω

- Seal Material: Viton O-ring

- Temp Range: -51°C to +177°C

- Min Temp Warning: -34°C operational limit

- Bend Radius: 25.4mm minimum

FluidLoc Technology

- Prevents lubricant migration

- Blocks internal wicking

- Seals at connection points

- Ideal for oil-rich environments

Mechanical Specifications

- Case Material: AISI 304 Stainless Steel

- Tip Material: Chemical-resistant PPS

- Max Torque: 45.2 N•m (400 in•lb)

- Optimal Torque: 15.2 N•m (133 in•lb)

- Thread Engagement: 0.75″ maximum

Certification Profile

- ATEX/IECEx Zone 1 & 2

- UL/CSA Class I Div 1

- NEPSI China Compliance

- Marine DNV-GL Certified

Electrical Performance

- Linear Range: 2.5mm (100 mils)

- Scale Factor: 3.94 V/mm ±10%

- Frequency Response: 0-12 kHz (±1dB)

- Output Signal: -1 to -18 Vdc

Installation Protocol

- Use thread sealant on UNF threads

- Apply 15.2 N•m installation torque

- Keep >25.4mm bend radius

- Maintain >-34°C operating temp

Support & Logistics

- Warranty: 12-month coverage

- Shipping: FedEx/UPS/DHL Express

- COO: Available on request

- Lead Time: 24-48 hours

Technical FAQ

Q: FluidLoc vs standard cable performance?

A: Identical electrical specs with superior sealing

Q: Pressure testing availability?

A: Custom testing through engineering department

Q: Vibration tolerance certification?

A: Meets API 670 Section 6.8.2 standards

Q: Minimum bend cycles rating?

A: 10,000+ cycles at minimum radius

Reviews

There are no reviews yet.