Introduction

GE 90-70 PLCs are workhorses in industrial automation. Many still run critical processes today. But aging hardware risks sudden failure. Smart preventive maintenance keeps these systems reliable. This guide shares proven strategies. I’ve applied these with GE systems across power plants and factories. Save costs and avoid downtime with these steps.

Why GE 90-70 Systems Need Special Care

Unlike modern PLCs, 90-70s use older components. Capacitors dry out. Connectors oxidize. Spare parts get scarce. I’ve seen plants lose weeks waiting for replacements. Proactive care prevents 80% of common failures. Treat them like vintage cars – regular upkeep is key.

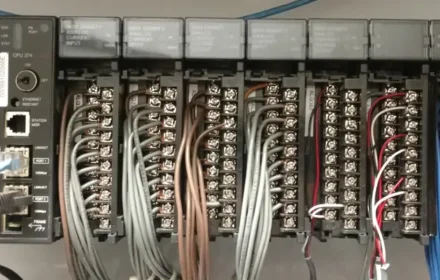

Monthly Visual & Cleaning Routine

Start simple. Dust causes 30% of overheating issues. Power down and inspect:

- Check for swollen capacitors (bulging tops mean trouble)

- Clean fans/vents with compressed air

- Examine terminal strips for corrosion

One cement plant reduced failures by 45% just with quarterly cleanings.

Power Supply Health Checks

Weak power kills PLCs slowly. Monitor these monthly:

- Voltage stability (±5% of rated value)

- Backup battery voltage (replace every 2 years)

- Grounding resistance (<1 ohm)

Tip: Use thermal cameras annually. Hot spots predict power supply failures.

Strategic Component Replacement

Don’t wait for failure. Replace critical parts early:

- Memory batteries: Replace every 3 years

- Cooling fans: Swap every 5 years

- Input/Output modules: Rotate spares yearly

Stock key spares like VME processors. I helped a refinery avoid $500k downtime this way.

Software & Backup Best Practices

Lost programs cause extended downtime. Do this quarterly:

- Verify program backups on separate media

- Test restoration on spare hardware

- Archive logic versions with change dates

Note: Always discharge static before handling modules!

Training Your Maintenance Team

Knowledge gaps are risky. Cross-train staff on:

- 90-70 architecture basics

- Diagnostic LED interpretations

- Safe module replacement procedures

Keep Your GE 90-70 Running Strong

Preventive maintenance adds 10+ years to GE 90-70 systems. Regular checks catch small issues early. Smart stocking avoids downtime. With care, these legends outlive newer PLCs. Need help? World of PLC Limited offers certified GE 90-70 replacement parts

Protect your investment now: Explore GE 90-70 Maintenance Solutions at World of PLC Limited →

| Model | Title | Link |

|---|---|---|

| IC697CPU789 | GE Fanuc Series 90-70 Triple Redundancy CPU (16 MHz) | Learn More |

| IC697CPX772 | GE Fanuc Series 90-70 CPU Module (96 MHz) | Learn More |

| IC697CPU732 | GE Fanuc Series 90-70 CPU Module | Learn More |

| IC697CPU781 | GE Fanuc Expandable Programmable Logic Controller CPU | Learn More |

| IC697CPU780 | GE Fanuc Series 90-70 Hot Standby CPU (16 MHz) | Learn More |