Understanding the Bently Nevada 3300 NSv System

The Bently Nevada 3300 NSv Metric probe is critical. It measures shaft displacement and vibration. Proper installation ensures reliable machinery protection. These probes integrate with control systems, like PLC and DCS. They are essential for modern industrial automation. This system provides crucial data for predictive maintenance programs. We must get the setup right from the start.

Pre-Installation Checklist: Essential Preparations

Before starting, gather all necessary tools. Verify the probe tip diameter is correct. Check the probe’s thread type and length. The target material must be a ferrous metal. Ensure the mounting area is clean and flat. This prevents measurement errors. Refer to the official Bently Nevada manual always. A clean environment is key for factory automation sensors.

Mounting the Probe Housing: Securing the Sensor

Mount the probe housing securely to the machine casing. Use a sturdy bracket or a pre-drilled hole. The housing must be perpendicular to the shaft surface. This ensures an accurate gap measurement. Tighten all locking nuts firmly. However, avoid excessive force. Proper mechanical installation directly impacts probe performance. Correct mounting prevents future headaches in industrial automation.

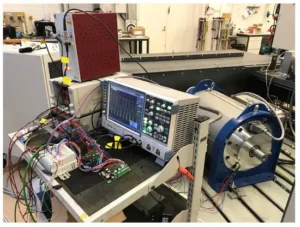

Setting the Critical Air Gap: The Key to Accuracy

The air gap is the distance from the probe tip to the target. It is the most critical setup step. Use a non-contact feeler gauge or a micrometer. Adjust the probe position precisely. The recommended gap is typically 0.5 mm to 2.0 mm. Consult the probe calibration sheet for the exact setting. An incorrect gap compromises linearity. Therefore, meticulous adjustment is vital for accurate vibration monitoring. This step ensures system accuracy.

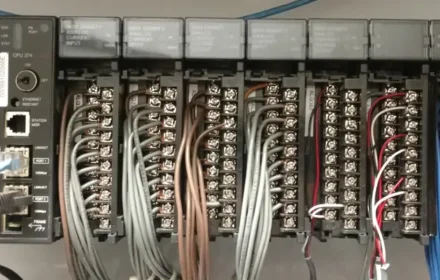

Cable Routing and Connection: Maintaining Signal Integrity

Route the extension cable away from high-voltage cables. Avoid sharp bends or pulling the cable too tightly. Proper shielding is crucial for signal integrity. Connect the probe to the extension cable securely. Then, connect the extension cable to the Proximitor. Use weather-proof conduit where required. In addition, ensure all connectors are clean. Poor connections introduce electrical noise into the control systems.

Author Insight: The Value of Proper Installation

Many field issues stem from sloppy installation. A small error here can lead to high maintenance costs later. Investing time in correct setup pays dividends. The Bently Nevada system is a benchmark in machinery protection. Its reliability depends on field technicians’ diligence. Proper installation is the foundation of high-quality vibration data. I recommend double-checking the gap setting always. This ensures the best performance and longevity.

Application Scenario: Turbo-machinery Monitoring

The 3300 NSv Metric probe is often used on large turbo-machinery. Consider a gas turbine application. The probe monitors shaft radial vibration and axial position. The data feeds directly into the plant’s DCS. This integration allows operators to shut down the turbine immediately if limits are exceeded. A properly installed probe provides early warnings. As a result, catastrophic failure is avoided, saving millions. This showcases the value of precise sensor installation in high-stakes environments.

World of PLC Limited offers a wide range of industrial control systems components and solutions. Need Bently Nevada probes or other factory automation parts? Click here to explore our product catalog and secure the high-quality components your system deserves.